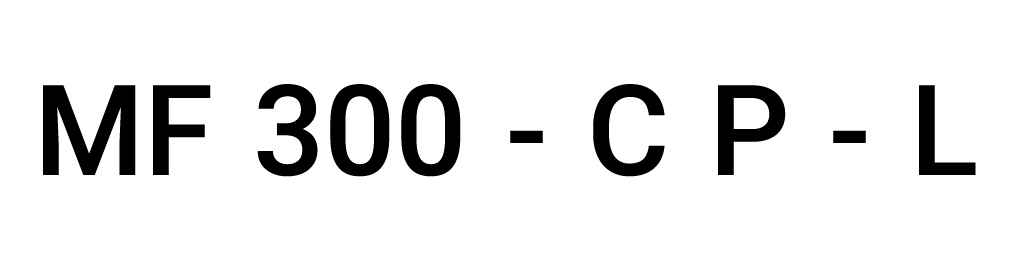

Mitsuei Concealed Ceiling Fan Coil (Rear Air Intake)

- Low noise, even at high speed

- Available in 6 sizes ranging from 300 to 1200 CFM

- Easy access to the filter for cleaning

- Easy access to air vent valve and coil drain cap

- Made in Iran

Details of Mitsuei fan coil components are provided below to guide your informed selection of a quality product:

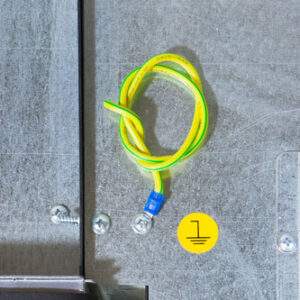

Provision of an earth (ground) wire in accordance with existing standards.

Equipping the coils with temporary red and blue caps to prevent dust and debris from entering before connection to the supply and return water pipes.

Piping can be configured from either the right or left side of the fan coils, based on prior order according to installation conditions.

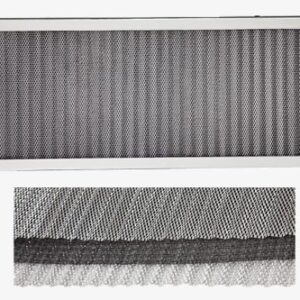

Easy filter cleaning to achieve optimal device performance (timely cleaning is necessary as the filter becomes clogged).

The need to maintain a proper distance between the access panel and the unit.

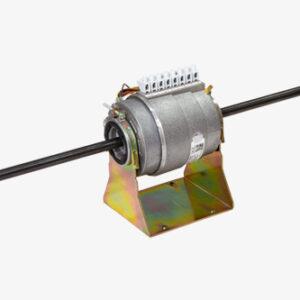

Easy access to the fan blade, electromotor, and air vent valve when the aforementioned installation conditions are met.

Easy access to the electrical box to change the electromotor speed.

Mitsuei fan coil

سایز یونیت

C : مدل سقفی توکار

D : مدل کانالی

پلنیوم

جهت اتصال چپ یا راست

A fan coil is a type of dual-purpose heat exchanger. As its name suggests, it is composed of two main parts: a fan and a coil.

A tangible example for understanding how a fan coil works is a car's heater. In a car heater, hot engine water enters the heater radiator (the coil), and passing through it, the coil heats up. The heater fan then blows air over the coil, projecting warm air into the car's cabin.

For more information, read the "What is a Fan Coil?" article in the Mitsuei Magazine.

We use fan coils in places where we want to control the temperature of each part of a building separately.

Furthermore, by using fan coils, we prevent the transfer of contaminants between rooms. Therefore, we recommend using various types of fan coils in hotels, residential buildings, office buildings, and hospitals.

021 562 77 114 – 16

021 562 77 510 – 13

تهران، آزادگان، احمدآباد مستوفی،

خیابان انقلاب، کوچه پارسا

کد پستی :

33131-93731