Mitsuei Concealed Ceiling Fan Coil

- Low noise, even at high speed

- Available in 6 sizes ranging from 300 to 1200 CFM

- Easy access to the filter for cleaning

- Easy access to air vent valve and coil drain cap

- Made in Iran

Details of Mitsuei fan coil components are provided below to guide your informed selection of a quality product:

Fan and housing construction considering multiple factors including airflow, pressure, noise, weight, material, etc.

Primary focus on noise reduction with attention to the rotating assembly (motor and fan)

Optimal air discharge angle using best manufacturing techniques

Dynamic balancing of fans to prevent vibration and disturbing noise

Use of galvanized steel sheet for fan construction (lightweight and high strength)

Dynamic balancing of fans to prevent vibration and disturbing noise

Use of permissible 1100 RPM speed in this fan coil model (maximum permissible fan speed 1300 RPM)

Formed aluminum fins

Fin collar connection to tubes via mechanical expansion using fully automated machines for maximum heat transfer

Seamless 3/8-inch copper tubes complying with ASTM standard, thickness 0.35 to 0.41 mm

Welding of copper tubes to headers and brass collectors

Coil testing at 400 psig pressure in a water tank

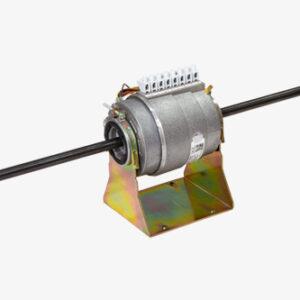

Design and production of fan coil electromotors specifically to meet the unique requirements of refrigeration systems (fan coils)

Proper operation of these electromotors at ambient temperatures up to 50°C, tolerance for voltage fluctuations up to 10%, and frequency variations up to 5%

Capability to provide a wide range of nominal speeds (7 different speeds) in these electromotors (3 selectable speeds)

Guaranteed quality, high efficiency, and very low acoustic noise in these electromotors due to unique design, advanced manufacturing machinery, and standardized testing

Manufactured by Electrogen Company under license from SISME, Italy

Use of 9mm thick self-adhesive elastomeric insulation

Elastomeric insulation as a suitable alternative to traditional insulation materials

Featuring the lowest heat transfer coefficient and playing a significant role in enhancing product quality and efficiency by preventing vibration and sound transmission

High resistance to accumulation of pollutants and moisture, inhibiting growth of bacteria, pathogens, and fungi

Connection of all components and plates with the best available imported screws in Iran

Mitsuei's proprietary mold specifically designed for mutually perpendicular plates to achieve maximum strength

No use of rivets due to generation of disturbing noise and excessive vibration during long-term operation

Galvanized component to protect pipe connection points to the coil

Identification of inlet/outlet water flow paths using guide labels

Production of two sensitive components via brass casting and forging to ensure balanced water distribution under pressure within the coil tubes and its proper outflow.

Inclusion of an air vent valve at the highest point of the water return line to purge air from the coil.

Water drainage through a transparent plastic tube to the drain tray.

Location of the electrical terminal and wire connections.

This metal box is positioned on the opposite side of the unit's piping to adhere to safety precautions.

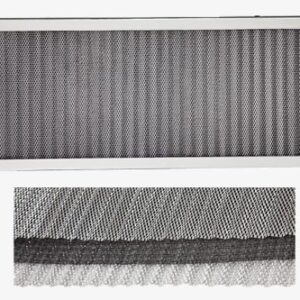

The fan coil filter includes 2 layers of aluminum mesh formed in a sinusoidal wave pattern.

A fine-mesh polypropylene fabric is placed between the 2 layers of perforated aluminum to maximize the absorption of fine particles.

These layers are housed in a frame made of 1.5 mm thick galvanized sheet, 210 mm wide, and in various lengths.

Easily removable for servicing and cleaning.

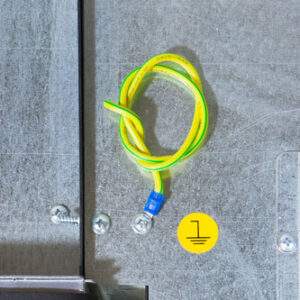

Provision of an earth (ground) wire in accordance with existing standards.

Placement of a drain tray beneath the unit, specifically under the coil, to collect and discharge water droplets from condensation.

Inclusion of a proper slope and a 1/2-inch pipe for draining the condensate to the outside.

The drain tray is made of 1 mm thick galvanized sheet.

External covering with 9 mm thick thermal insulation foam.

An inner coating on the tray to prevent corrosion.

Equipping the coils with temporary red and blue caps to prevent dust and debris from entering before connection to the supply and return water pipes.

Piping can be configured from either the right or left side of the fan coils, based on prior order according to installation conditions.

Possibility of connecting a fresh air duct to one side of the unit.

A 10 cm diameter circle is provided on the unit body (as shown in the adjacent photo). If a fresh air system is designed, it allows for mixing up to 40% of the intake air with fresh air (removable by the installer).

All body components of the fan coil unit are made of 1 mm thick galvanized sheet.

All panels are laser-cut.

Minimal noise even at high speed due to balanced fan blades (provided installation is proper and the unit is level).

All internal spaces are covered with suitable 9 mm thick sound insulation.

Use of the highest quality materials and adherence to packaging standards to ensure the product's integrity during transport and handling to the final site of operation.

The unit is shrink-wrapped after quality control approval to prevent dust and small stones from entering the device (before final commissioning in building workshops).

Easy filter cleaning to achieve optimal device performance (timely cleaning is necessary as the filter becomes clogged).

The need to maintain a proper distance between the access panel and the unit.

Easy access to the fan blade, electromotor, and air vent valve when the aforementioned installation conditions are met.

Easy access to the electrical box to change the electromotor speed.

Easy installation with metric screws to the metal frame embedded in the false ceiling.

Ability to connect the unit's air output to a flexible duct using the flange and holes on the edge of the fan coil's outlet.

Application of quality assurance and control principles and fundamentals towards producing an excellent and flawless product. Conducting numerous tests, including vibration, noise, motor speed, torque, and output air volume and velocity, to enhance quality. Quality control on incoming components, during the production process, and on the final product.

Airflow testing with a CFM measurement device.

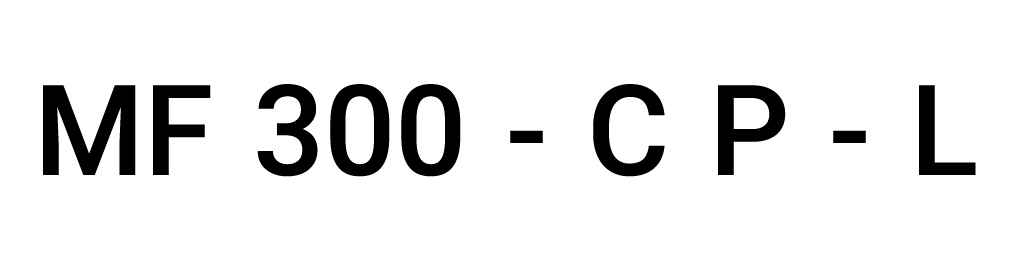

Mitsuei fan coil

سایز یونیت

C : مدل سقفی توکار

D : مدل کانالی

پلنیوم

جهت اتصال چپ یا راست

A fan coil is a type of dual-purpose heat exchanger. As its name suggests, it is composed of two main parts: a fan and a coil.

A tangible example for understanding how a fan coil works is a car's heater. In a car heater, hot engine water enters the heater radiator (the coil), and passing through it, the coil heats up. The heater fan then blows air over the coil, projecting warm air into the car's cabin.

For more information, read the "What is a Fan Coil?" article in the Mitsuei Magazine.

We use fan coils in places where we want to control the temperature of each part of a building separately.

Furthermore, by using fan coils, we prevent the transfer of contaminants between rooms. Therefore, we recommend using various types of fan coils in hotels, residential buildings, office buildings, and hospitals.

021 562 77 114 – 16

021 562 77 510 – 13

تهران، آزادگان، احمدآباد مستوفی،

خیابان انقلاب، کوچه پارسا

کد پستی :

33131-93731